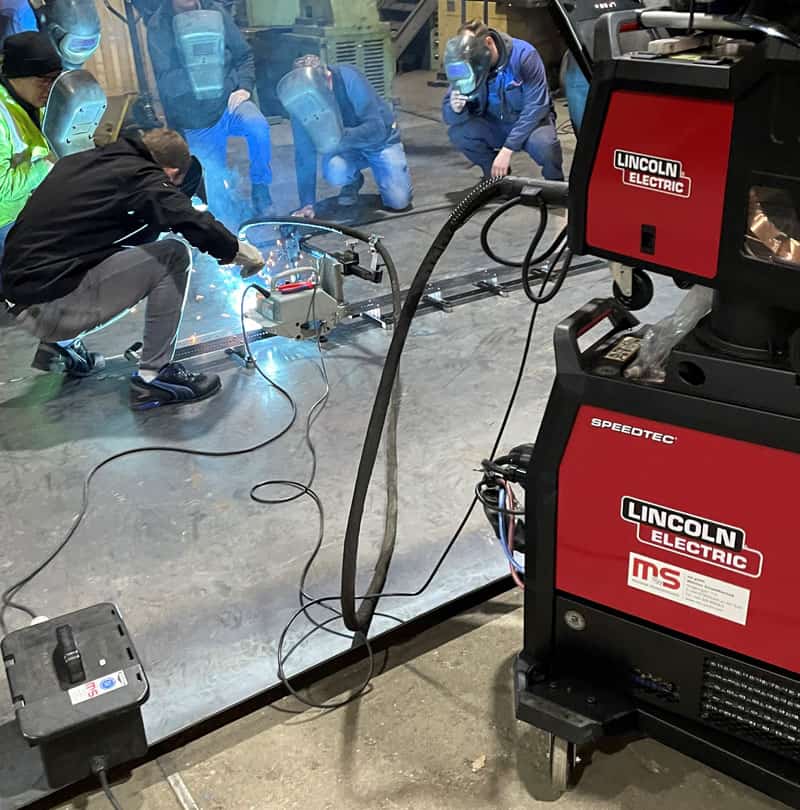

Gullco tractor systems

Gullco tractor systems are successfully used worldwide for cutting and welding tasks on flat or curved sheets and tubes. Gullco tractor systems can be used without a guide rail, on flexible, semi-rigid or rigid rails. Switchable magnetic bridges, vacuum fasteners or angle irons can be used to fasten these rails. With our tractor system you increase your productivity and the quality of your welds.

Functionality

The guide rails are aligned parallel to the weld seam. The welding tractor, which moves along the rail, guides the welding or cutting torch along the seam, allowing welding or cutting of long distances without interruptions. The rail sections are endlessly extendable and can be positioned easily and quickly on the component. The travel speed can be continuously adjusted on all tractors and can also be readjusted during the cutting or welding process. Due to the high holding force of our rail fasteners, our tractors can be used in all positions, even overhead.

Areas of application

Gullco tractor systems are mainly used in plant, apparatus, ship, bridge, pressure vessel, steel and tank construction. They are suitable for many welding processes such as MIG/MAG welding with solid and cored wire, submerged arc welding or cutting processes such as oxyacetylene cutting or plasma cutting. Other tools such as induction heating heads (Miller’s Rolling Inductor) or saws can also be guided by our tractor systems. Due to the extensive fastening options, the rails can be used on all materials.

Accessories

Gullco’s tractor systems can be enhanced with a variety of accessories such as linear or radial pendulum units, mechanical or electrical height sensing, tactile seam tracking systems, remote controls, motorized rack and pinion enclosures, auxiliary arc start relays, machine torch brackets or heat shields. We can offer you the right accessories for almost all applications. Please feel free to consult with our knowledgeable sales staff.

Service workshop

We as Gullco Germany are a certified service point. Thanks to our many years of experience, our expertise and an extensive stock of spare parts, your machine will be repaired and subjected to an electrical test quickly and reliably. Modifications such as additional arc start relays or gear ratios, for higher travel speeds, can also be installed by our qualified personnel. You can find more information about our testing service in the link below:

Economic efficiency

Due to the precise guidance and the constant guiding speed, a high seam quality and reproducibility is achieved. The duty cycle of the torch for an average welder is about 30%, for many customers, thanks to our systems, we have increased the duty cycle to over 70%. The use of our tractor systems increases quality and productivity, while at the same time lowering the cost of your welding or cut-off and reducing the workload on the operator.

Our machines at a glance

-

100 seriesSimple operation and quick setup make the KAT®100 particularly well suited as an entry-level model for a wide range of applications.

-

200 seriesThe KAT®200 features an extremely robust die-cast housing, programmable control and optional limit switches.

-

300 seriesThe KAT®300 includes all the features of the 200 series, but the weight, size and accessory settings have been optimized for user-friendliness.

-

MoggyThe Moggy welding and cutting tractor is designed for trackless use. This tractor requires direct guidance on the component or on an angle iron. Straightening times for attaching and aligning the rail are completely eliminated.

-

SAMThe Sam welding and cutting tractor includes all the functions of the Moggy tractor, but is much larger and has a higher load capacity. It is preferred for submerged arc welding (SAW) and multi-head applications.

Our tractor systems at a glance

-

Increase the seam quality and productivity, at the same time relieving the operator

-

Are used in plant, apparatus, ship, bridge, pressure vessel, steel and tank construction

-

Can be used on all materials and also on preheated components

-

They are suitable for many welding and cutting processes such as MIG/MAG welding with solid and cored wire, submerged arc welding, oxyacetylene cutting or plasma cutting

-

Available for rigid, semi-rigid or flexible rail

-

Accessories such as shuttle units or seam tracking systems can be retrofitted at any time

-

certified service point for Gullco machines

-

Different models available for many requirements

Frequently asked questions to Gullco tractor systems

We will be happy to demonstrate our machines at your premises or in our workshop. Make an appointment today.

Product identification is not always easy, our trained staff will be happy to assist you. Send us pictures of your application and we will provide you with a customized quote.

We are a certified service point for Gullco and can repair your machines quickly and reliably. We will be happy to provide you with a cost estimate in advance.

Our rental fleet includes over 10 tractor systems, which we can provide you with for the repair period in exchange for a rental rate.

Before you send the tractor to us, you should contact us by phone. Many problems can already be solved there, as often only the programs in the controller have been adjusted or small errors are present.

Contact us

Do you have any questions about our services or products? Contact us. We are looking forward to you and your projects!

Call us

Write to us