ITW Megafil cored wires

Gas shielded flux cored wires were developed mainly for welding structural steels and thick materials. They offer higher process reliability than solid wires, have a higher deposition rate and can be used in constrained positions. All of these advantages result in a higher production rate than solid wire or electric hand welding with fewer defects in the weld.

Production

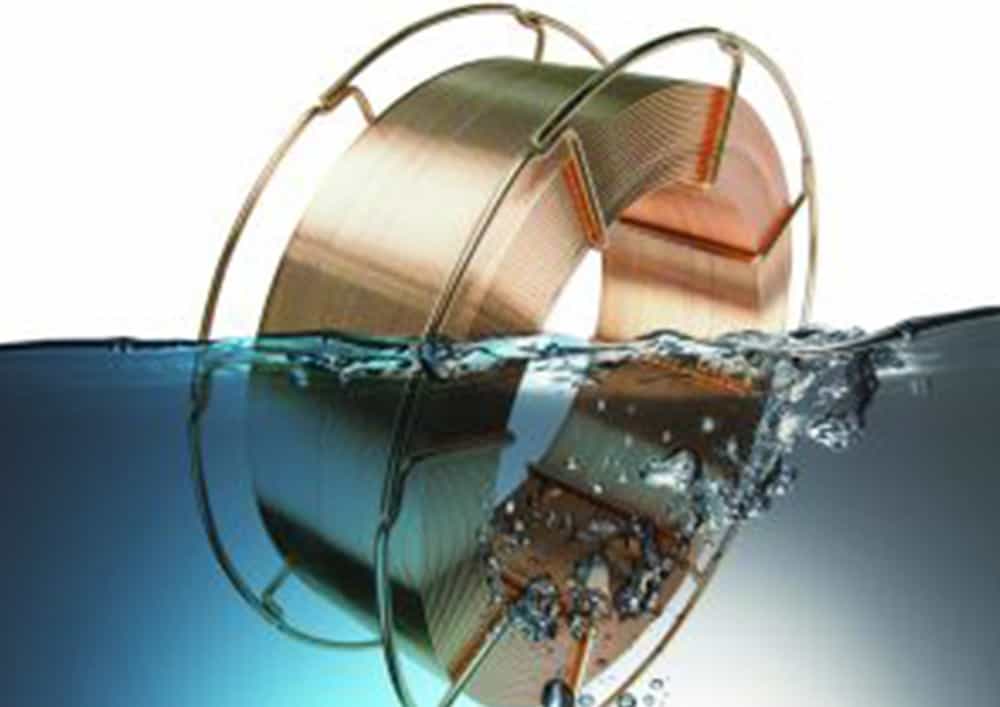

The unique production technology ITW Welding uses to produce MEGAFIL® seamless flux cored wire provides valuable product benefits to the end user. The manufacturing process is divided as follows: Strip is formed into a tube, HF welded and then drawn to the filling diameter. In the next step, the tube is filled with agglomerated powder by means of a vibration system. Then the wire is annealed, drawn to the final diameter and coated with copper. Finally, the wire is precisely wound onto different spool sizes in layers. The result is a completely closed flux cored wire with an extremely dry powder core that does not absorb any moisture during storage and welding.

Approvals

MEGAFIL® seamless cored wires are available for most steel grades with a wide range of approvals from societies such as ABS, DNV, LR and TÜV. The wire can be ordered with a 3.1 certificate that lists the real values of chemical composition and mechanical properties of the delivered batch.

Brands from ITW

We can offer you not only filler wires from ITW, but also welding consumables from Hobart and Elga.

All advantages at a glance

-

Higher deposition rate due to increased welding parameters

-

Higher process reliability, can be used in constrained positions and produces fewer defects in the weld seam

-

Prevention of hydrogen-induced cracking . The hydrogen content in the weld metal, tested according to EN and AWS, is below 4 ml/100 g Typical values are below 3 ml/100 g

-

Special precautions for storage are not necessary. Can be stored indefinitely like solid wire. No risk of moisture absorption

-

No need for re-drying, even after storage in a humid environment

-

Resistant to moisture absorption even after removal from the package, e.g. when mounted on wire feed unit

-

No voids in the filling – thus reliable weld metal properties

-

Copper coating for optimum welding current transfer between contact tip and wire and to minimize contact tip wear

-

Excellent wire feeding characteristics and twist-free entry into the contact tip due to carefully controlled dimensions, cast and helix. Ideal for robot welding

Frequently asked questions to ITW Megafil cored wires

Yes, there are many areas in industry where self-protecting cored wires are used. For more information, visit our Innershield section.

The production process of cored wire is much more complex than the production of solid wire. Furthermore, the use of cored wire offers many advantages, such as a higher deposition rate, compared to solid wires. This justifies the higher price.

Gas-protected cored wires are divided into 2 types, seamed and seamless cored wire. Seamless cored wires are completely closed and cannot absorb moisture from the environment. Seamless cored wires can be used in all climatic conditions.

All cored wires, whether slag-forming or slagless, can be used on ceramic bath fuses. Some types of our bath fuses are designed to give the slag room to spread.

We will be pleased to provide you with a small spool of cored wire for test purposes or to carry out test welds at your premises. Just contact us!

Contact us

Do you have any questions about our services or products? Contact us. We are looking forward to you and your projects!

Call us

Write to us